We have a full complement of tuning and upgrade products for all sorts of Vespa machines which we intend to fit and analyse over the coming months, in order to assist readers to make informed decisions on what parts and components are right for them. We started the journey with a standard PX125 and will continue to develop the machine over the winter months. Now we take a leap forward with the BGM177 kit…

QUICK REVIEW

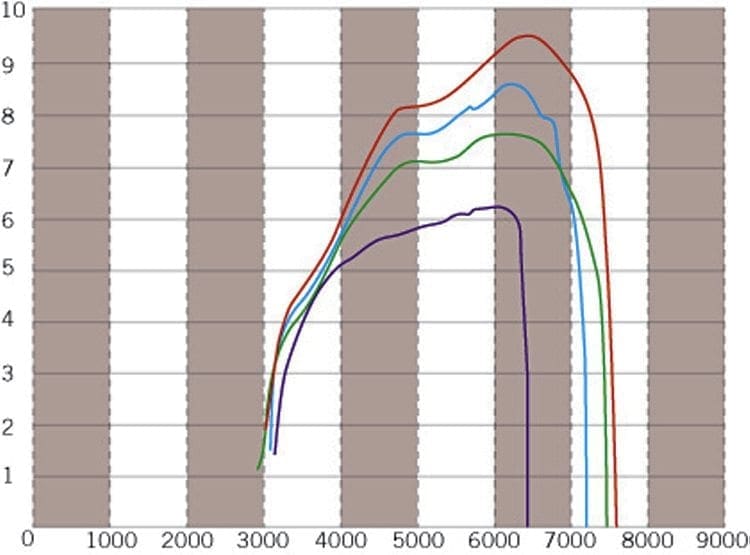

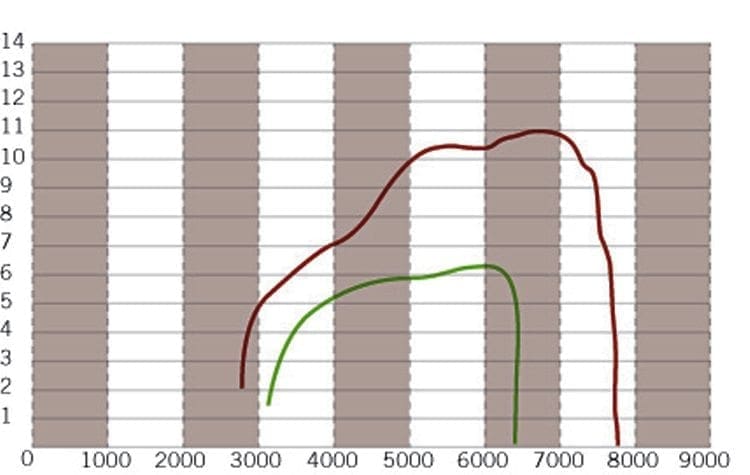

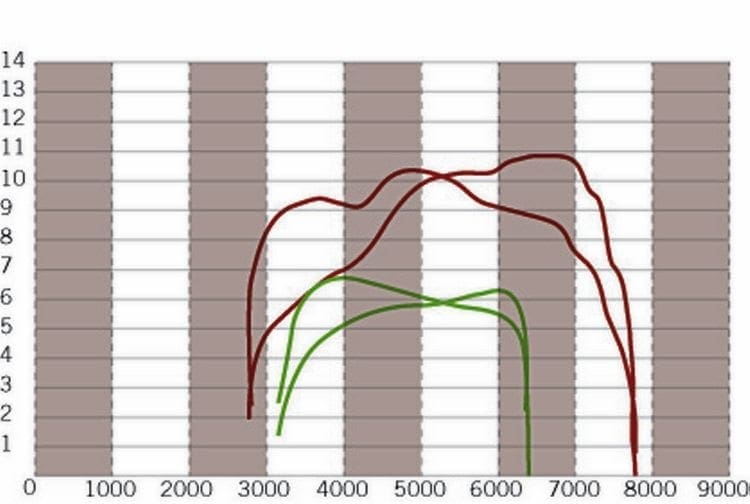

We established a baseline figure of 6.3bhp for a standard 2015 Euro 3 engine PX125 fitted with cat exhaust. The power peaked at 6000rpm and offered no over-rev. Thus it took around 29 seconds to accelerate from a standing start up to 50mph on the flat. The standard machine would wheeze out 45mph uphill, 50mph on the flat and only 52mph downhill. After fitting a SIP Road 2.0 pipe, we gained 1.5bhp, nearly 1000rpm of over rev, dropped nine seconds off the 0-50mph, and although uphill and on the flat speeds only changed by 2mph, the top speed downhill gained 5mph due to over-rev now being available. Following that, we skimmed the head and fitted a base packer which took us up to8.8bhp. Lastly, we mildly ported the exhaust port and finished at 9.8bhp. This is very similar to the power of a bog-standard PX200, so not a bad result. The 0-50mph time dropped to 18 seconds and the scooter will sit at just 50-54mph all day long, a bit less into strong headwinds and up hills, but will hit nearly 60mph when balls-out down a big hill.

NEXT MOVE

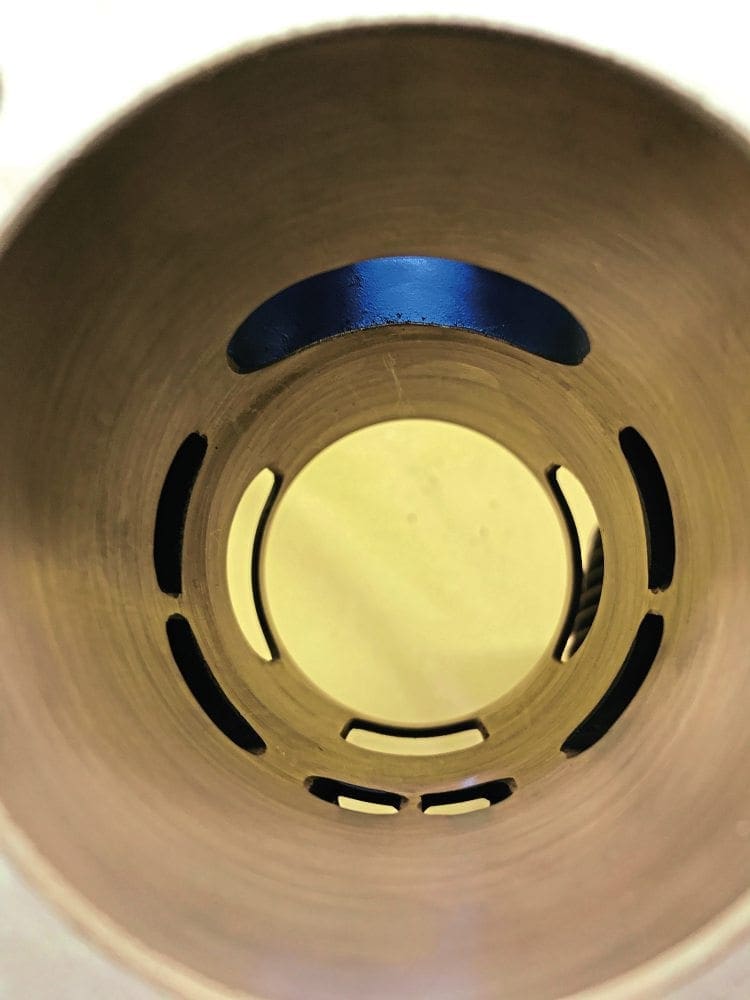

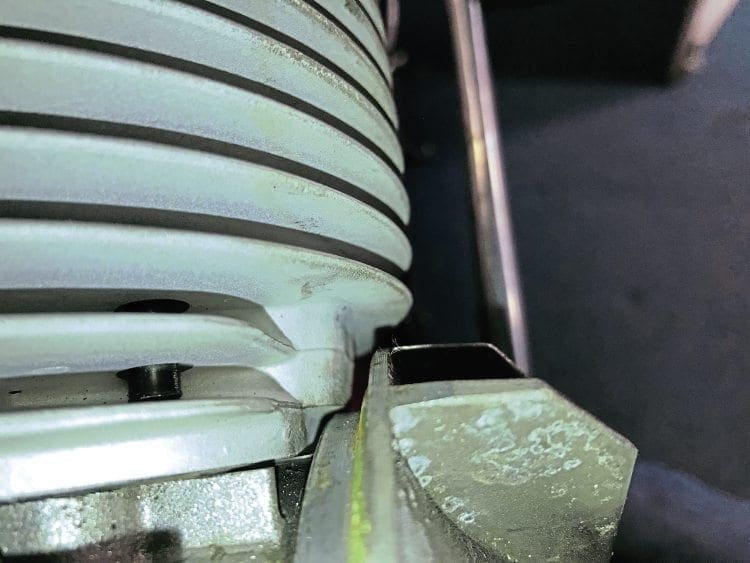

The BGM177 kit is a fine piece of engineering, but then most items from Scooter Center are. It’s a Nikasil-lined alloy kit with CNC machined head. Included with the cylinder, piston and head are a selection of gaskets (top and bottom) for various configurations. We plan to simply bolt off (old kit) and bolt on (new kit) with no other changes, to see what a home mechanic or DIY tuner might gain on a Euro 3 engined PX125. The kit itself has a rather lovely trio of cylinder-base transfer ports, which match the standard PX casings nicely. The beauty however is that they have a large ‘lip’ on them, so should the desire to port your casing take you, you can simply Dremel off the lip to match — perfik. The kit also comes with quite a comprehensive data-spec sheet; I wish all cylinder manufacturers gave us these because they are very helpful.

The data provided confirms port timings on our standard 57mm stroke crank of 118 degrees of transfer (almost identical to our tuned factory cylinder) and 171 degrees of exhaust (8 degrees higher than our tuned factory cylinder). The port area is comprehensively bigger, and the timings are a vast improvement, so this displays good potential for significant power increases over our ‘home tune’ cylinder — if all other components and factors are conducive to such making gains (I’ll explain that bit later).

FITTING THE GOODS

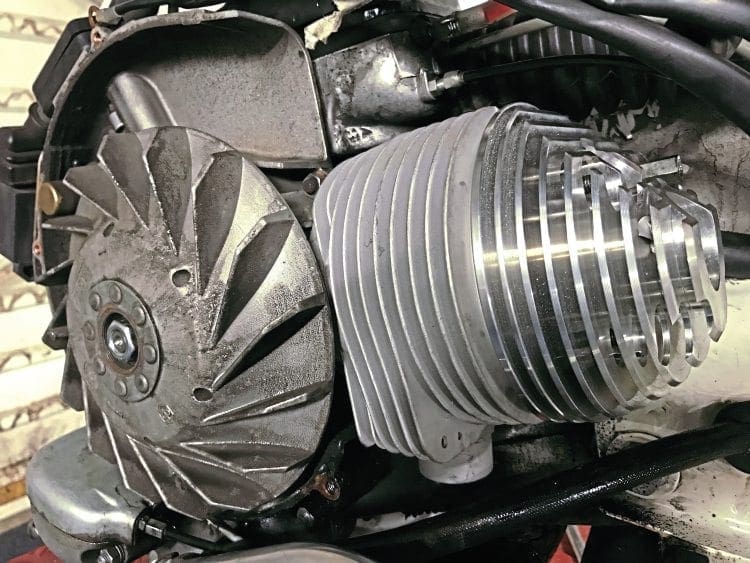

Simply remove the head cowl, slacken off the exhaust downpipe, undo the four head nuts, remove cylinder head, then double-nut the studs for removal, slide off the cylinder, and remove the piston via the gudgeon pin and circlip. Piece of cake. So we just pop the new cylinder straight on right? Wrong… the BGM kit doesn’t allow you to retain the original electric start tooth gear, the fitment is too tight. So this means either fitting a new flywheel with no tooth gear (not as straightforward as you think — see further info on Euro 3 restrictions) or heat up the flywheel (we just sat it in front of a fan heater for 15 minutes) and then gently/evenly tap the tooth gear off.

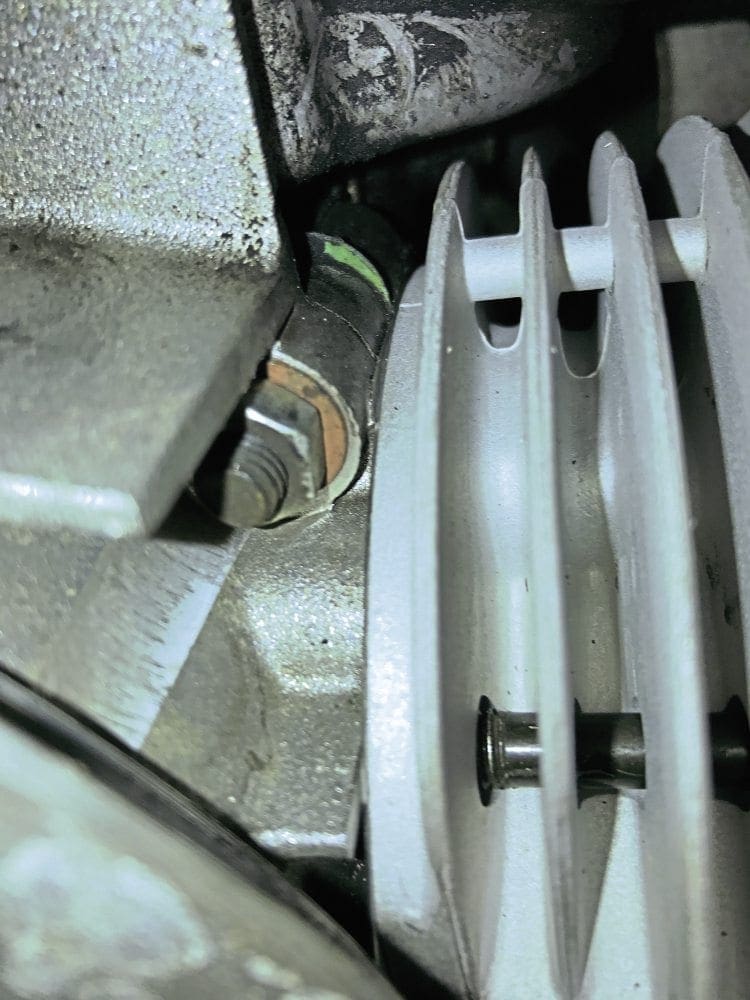

So it’s fan cowl off, flywheel nut off, remove flywheel with correct puller, ‘sweat’ the tooth gear off as noted above, refit flywheel and torque the nut. Next make sure your engine casings are clean, and the way I fit the BGM kit is as follows: On the workbench I put the piston circlip in one side of the piston (the side which will be closest to bodywork), fit the rings to the piston, oil the bore with two-stroke and slide the piston into the bottom of the cylinder. I then fit the base gasket onto the cylinder and slide everything into position on the engine, and fit two cylinder studs finger tight to support the cylinder. I then proceed to pop the small end bearing, gudgeon pin and circlip into place, before then properly fitting all four cylinder studs. On a standard kit it’s very easy to slide the kit onto the piston/rings with the piston already fitted to the con rod, as it has a lovely taper at the bottom of the spigot. But the thin/sharp spigot of the BGM kit, combined with the tight/new rings makes sliding a kit on when the piston is already fitted to the engine a little difficult, so I negate that stress by pre-fitting the piston to the cylinder on the bench. That’s just my tip, you do it the way that suits you best. Once that’s all in place, it’s just a case of popping the exhaust back onto the new stub, torqueing the head down and refitting the cowls.

So we have just switched from an old cast iron 125cc cylinder with poor port timings and port area, to a new fancy alloy/Nikasil kit with 177cc, bigger port area everywhere, longer exhaust duration, better blowdown timing, better head design, and better piston. The gains must be huge, right? Well, no, wrong again. This is the bit where I explain the previous remark: If all other components and factors are conducive to such gains’.

BGM177 ON THE DYNO

This is a 2015 PX125, which means it is fitted with the Euro 3 compliant engine which was introduced from 2011 onwards. Prior to that, Piaggio was quoting bhp figures of around 9bhp for the 125cc PX Vespa. But the 2011 model onwards was a lowly 6.5bhp (confirmed as 6.3bhp on this machine using my dyno).

Quite simply, in order to meet the stricter emission laws, Piaggio was forced to introduce a number of restrictions, namely a more restrictive exhaust (full of honeycomb baffles), a more restrictive air filter, lower inlet timing, and a Chinese branded ignition system which is limited to 7000rpm and isn’t interchangeable with existing PX ignition components.

Any two-stroke engine’s final power output is a result of its cumulative components. So in our example, the humble 125cc cylinder had potential to easily go from 6.5bhp up to 9.8bhp with only a few tweaks and component changes. The Euro 3 restrictions allowed this, but had we tried to take it any further we would have been fighting against the other limiting factors and restrictions.

Come the introduction of a 177cc kit in all its glory with its much better port layout, the layman might expect to see huge gains. But due to the other limiting factors, this is not yet the case. BUT! Unlike the small 125cc kit which had much lower potential for its final power figure, the BGM is a superior item and has a significantly better starting point, with huge potential… once we identify the other components that we wish to exchange/upgrade, in order to free the full power of the kit. I dare say a marginally better power figure would have been found if fitted to a pre-2011 PX125 with fewer factory restrictions.

NEXT MOVE

So what next for tuning options?

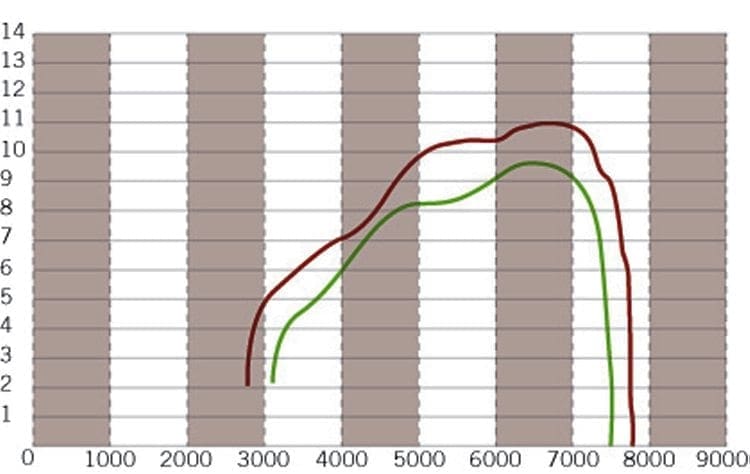

Well firstly I need to do justice by the BGM exhaust which matches the kit. The SIP Road 2 has been a real boost to the factory cylinder in both tuned and un-tuned formats, but BGM has its own exhaust for the kit, so my next step is to see how that shapes things. The SIP and BGM exhausts will be in constant use throughout the feature, to see how each option offers slightly different results on different component specs.

The next item is the crank: From my experience in Vespa tuning, one of the biggest limiting factors in any tune, is the inlet timing. The inlet duration on a Vespa PX is controlled by the crank, where a cut-out in the web passes by the inlet port in the casing, and during that period the fuel/air inlet charge is drawn in. This can be seen by taking off your carb top and filter, opening the throttle and pressing the kick-start. You will see the crank seal the port closed, until it revolves to the inlet cut-out, that portion is the inlet duration. On average PX models pre-2011 we would expect to see standard inlet timing of circa 150-155 which is very conservative anyway.

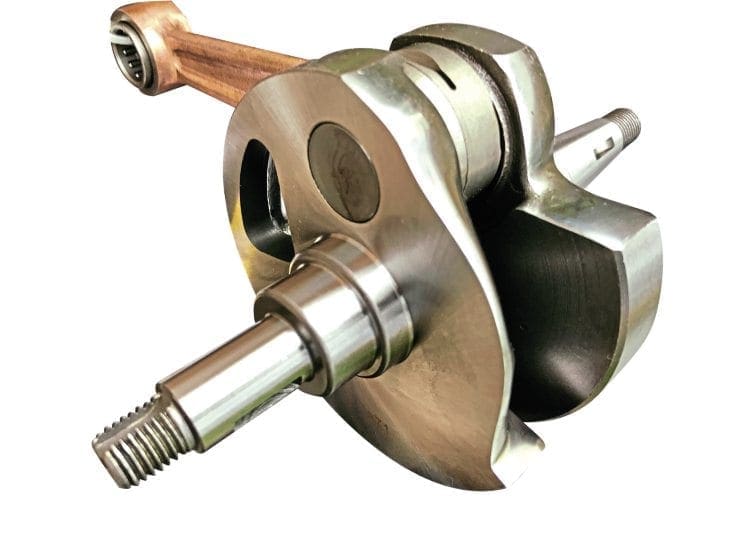

An aftermarket ‘tuned’ crank might see around 180-185 degrees of inlet (part before TDC and part after TDC — but we will come to that in later editions). I’d expect this Euro 3 engine to be around 140 degrees (or lower). We could cut the existing crank, but I want to add something else to the mix: long stroke! We will fit the 60mm BGM crank (standard stroke is 57mm) which will not only take the engine up from 177cc to 187cc, but it will raise transfers to 123 degrees and exhaust to 173 degrees, with 25 degrees of blowdown – this is a great touring spec and will work well.

We also need to take a look at the ignition. Although a 7000rpm rev limit hasn’t been a problem on the 125cc factory cylinder, the fact is that we may want to rev on a bit more with later developments. I’ll talk in more detail about further tuning upgrades after this stage, in coming editions, but over the winter I have made plans for a bigger carb (26mm Spaco – retaining autolube), a beefier clutch, and an up-gear kit too.

We also need to look carefully at the brakes, suspension, wheels and tyres to accommodate all that extra speed and power… it’s going to be a long winter!

AND THE PX200?

Well, poor Stan seized his PX200 and had to have it rebuilt; he then holed a piston and so fitted a new top end, but then brought it for dyno… and I’m sorry to say that I condemned it.

In a fit of petulance he bought a new donor engine which he is busy rebuilding to standard factory spec. Once it is built I will dyno for base-level figures (expecting around 9bhp) and then start the same process. We also have a SIP road 2.0 exhaust for that, to see how well it works on a 200 cast cylinder.

Then we also have a nice Polini combination package from VE, of a Polini 210 (alloy) kit and matching Polini exhaust. It will be great to get these two items fitted onto an otherwise standard PX200 and see what power increases they bring both individually, and when they are combined.

That’s all we’ve got room for this month, stay tuned.

NON-TUNING ITEMS

Sat nav

I’m a geographical dimwit, there I said it. I literally have no sense of direction, and can get lost on the simplest of routes. We all have our weaknesses, and apart from women and alcohol, route planning is mine. So I’ve promptly installed the TomTom Rider 400. It’s hardwired into the ignition wires behind the horncast cover so is powered up/down via the ignition on/off switch. I have a Bluetooth headset inside my helmet, and this TomTom paired up to it, so whether it’s route planning, traffic warnings, or speed camera alerts, it all comes in through my headset.

The menu is very simple and intuitive, with easy route planning, extra stops easily added, and regular destinations planned in. I did briefly flirt with the cheaper TomTom VID, which is a smaller unit, powered by USB recharger and which links to your mobile phone. But in all honesty I found that lacking in features, and it was a faff clipping it on/off for re-charging, and having to link in with an app on my phone.

This Rider 400 is a comprehensive ‘standalone’ bit of kit, and with lifetime euro maps available it can guide you anywhere. I rate it highly. I also gave Stan the VI0 to try, he’s old school and his sat nay involves writing road numbers on his mirrors, so it will be interesting to see how an older-schooler gets on with modern tech. A follow-up report beckons!

RACKS

I hate racks. I shouldn’t be against them… but I am. I hate racks in the same way I hate mirrors and chrome bumpers/trim. I like, nay I love, the classic sleek lines of an Italian scooter and see anything which detracts from it as unnecessary tat. Adding a clumsy looking sat nay was a big enough ordeal for me, but without one I’d be lost somewhere in the Scottish Highlands right now. Plus it gives me accurate GPS speeds for tuning tests, so that’s a done deal.

But racks, I don’t like them. However, without a rack I’m not fitting very much luggage on my scooter am I? Like the sat nav, I need a rack, as it makes my life easier and stops me having to faff about trying to secure stuff elsewhere. And let’s face it, basically I can just carry more stuff to a rally with a rack. So given my awkward relationship with racks, what are my criteria if I have to fit one It needs to be a) easily removable after the event b) installable without drilling c) good-looking d) functional for its purpose. It’s fair to say the FA Italia rack from SIP covers all bases. It only takes a few minutes to fit, leaves no holes/marks when removed, has a decent carrier space for luggage, and damn it all… dare I say it? It actually looks good too. I swore I hated racks but I’ve left this one on even after the journey, it must be growing on me.

Words & Photographs: Dan Clare