Not just any old engine, but a five-speed 225cc engine!

After many years of loyal service I decided my Li 150’s engine needed some TLC, and to build a new motor for it in the mean time. Not just any old engine of course, but a five-speed 225cc engine!

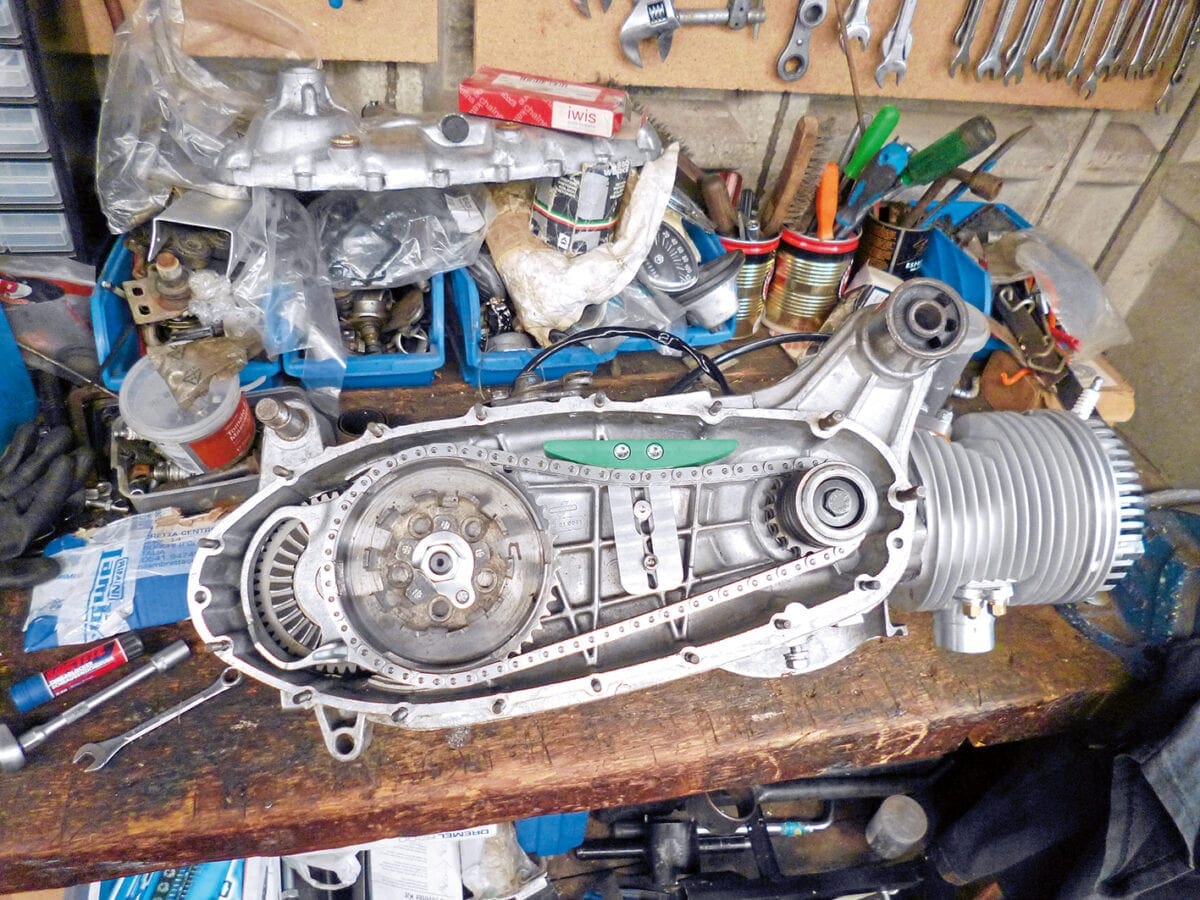

The Cyclone five-speed gearbox had been fitted by JB Tuning, my decision being John had the experience and know-how… as well as a better set of feeler gauges than myself. I also got him to knock in an AF crankshaft for me too, along with new bearings and seals. I’ve ridden a couple of five-speed Lambrettas recently, but was now very much looking forward to getting my own on the road.

Build up

With the potentially tricky work done, I took the motor home and set about building the rest of it.

On the dirty side of the engine I again took Sticky’s advice (and his 19 tooth front sprocket) to run a 19/46 set up. I also fitted an 82 link Iwis chain, LTH pull down tensioner and a four-plate clutch with LTH springs. On the clean side I have a BGM electronic ignition which features their own stator plate and Indian flywheel.

At the top end we have a new BGM MRB RT 225 kit, which was launched a couple of months ago. It is based on MB’s old kit developed in the UK a couple of years ago, and now put into production by Scooter Center Köln (SCK) in Germany under the BGM banner. The RT means Race Tour and the concept is it can offer the customer either option, depending on how you set it up.

It has an ali barrel, a head that’s CNC machined in Germany and forged piston kit with two 1mm Japanese piston rings. The head has the regular four stud holes plus four bolts for extra security and a recess into the barrel, and the exhaust manifold has four stud holes around it too. It’s all looking good, the head in particular a work of art I wasn’t sure whether to fit to the scooter or display on top of a book case at home!

I fitted the kit straight out of the box – which was a doddle as you’d expect – the idea being to see where we are from there. Next came the carb manifold, although I had a new MB one and unfortunately it wasn’t too good. I’d last bought one of these two or three years ago and hoped things had improved since, but sadly it seems not. The problem is that the manifold is roughly cast and not cleaned up and the outer groove for the carb rubber to locate into has not been machine finished as MB manifolds used to be in the good old days. Checking around it seems I’m not the only one to suffer with these manifolds, which is a shame. Time for a Dremel session then…

Once all fitted, the next stage was to cut the head cowling to fit around the new kit. A marker pen, tin snips, Dremel and patience were required.

Exhausting

Next, the exhaust; now over the last few years I (and my good lady) have spoken to numerous scooter shops and companies about making a clubman style pipe with a separate spring mounted stub, along the lines of a typical sports exhausts for your TS1 engine.

Vespa riders I’ve probably lost you here… but basically, in my opinion, one of the biggest faults of the Lambretta is its exhaust. It bolts on to the manifold (in a similar way to a Vespa T5), but with a gasket and when that blows and needs replacing (by the side of the A30 on the way to Woolacombe a couple of years ago for example), it takes you bloody ages to change because the exhaust nuts are so inaccessible. There is little space there anyway, and the angle of the U-bend restricts it further.

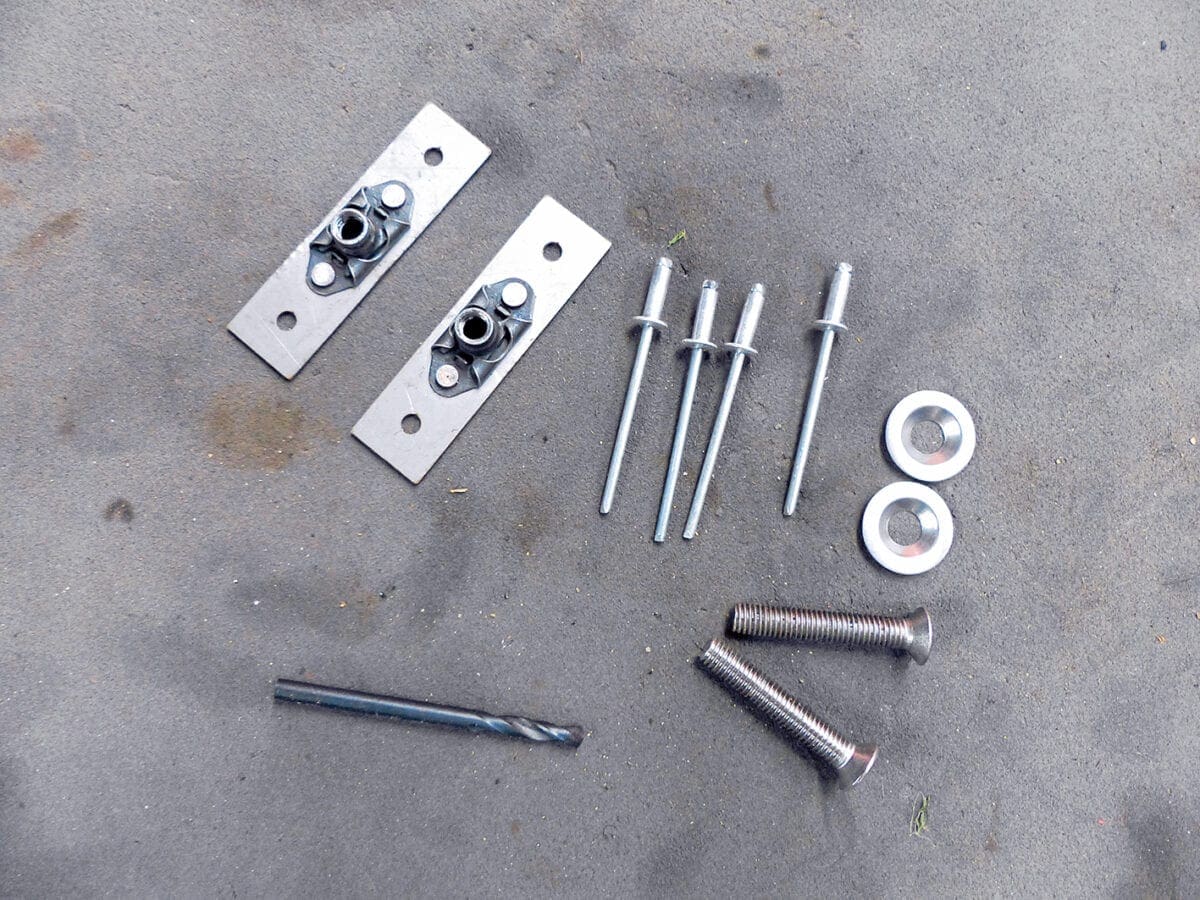

The BGM MRB Clubman has a separate stub however – Yippee! Thank you everyone concerned! This means that once this short stub is fitted to the barrel, the rest of the exhaust is spring mounted to it, which together with a new type of front mounting bracket (with captive nuts) makes it far easier to remove if, for example, you’re changing the clutch. And if the gasket blows, then the nuts on the stub are now accessible too.

So looking forward to these new exhausts were we that we got two, one for my new 225 and one for my missus to fit to her Italian GP200. Unfortunately, they weren’t without problems, despite fitting and removing the parts several times to make sure we were doing it correctly.

The first exhaust (for a 1969 Lambretta GP) needed the front bracket holes fettling to line them up correctly before both bolts would go through. We also discovered that the bracket underneath the engine did not line up and needed enlarging, while the front edge/lip of the exhaust body fouled on the scooter’s centre stand. Although the design of the exhaust does allow some adjustment, it was not enough. The tail pipe bracket also fouled on the kick-start, but this was solved by turning it around.

We tried the second exhaust on a SIL engine with a TS1 top end and then the RT, and found also that one of the holes in the front engine mount bracket did not line up correctly (the one nearest to the engine again), but it was closer.

However, once I had made all the adjustments with the Dremel the exhaust did fit well and was very easy indeed to remove and refit, especially as it turns out that the brand new kick-start plunger I’d just fitted was rubbish and needed replacing immediately!

I then also found the BGM exhaust’s barrel stub would not fit between the fins on the BGM MRB RT 225 barrel. I spoke to the guys at Scooter Center who told me that measurements were taken from an original Innocenti barrel for their kit and that it was in fact their new Clubman that was to blame, which is a shame, but at least I got to use my Dremel again… and a few minutes later I’d got two razor thin fins, but can fit the exhaust.

Now I’ve spoken to a handful of dealers and customers who’ve fitted these exhausts and a number have experienced similar problems, so I know it’s not just me. When I asked one shop owner what he’d done about it he told me nothing, because he was so used to scooter parts not fitting (from any manufacturer, not just this particular exhaust I hasten to add!) that he could no longer be bothered to package it up, return it, await a replacement part being sent out, and all the hassle that went with it.

Again SCK was very concerned about the feedback we gave, but appreciated our comments which they in turn have passed on to their parts manufacturer. They’ve also told us that as from now, they won’t let any of their Big Bore Clubmans leave SCK without first being checked for alignment. So all credit to the folk in Köln for doing the right thing here, and a reminder to all you out there in scooterland; while we all want parts that fit and work perfectly, when they don’t please do tell the manufacturer. I know us British would rather suffer in silence than complain, but how else can manufacturers learn to improve things?

On the run

So how does it go? Well I finished my engine off with a Dell’Orto PHBH 30mm carb as I know where I am with them regarding jetting. It’s rich at the moment, but for running-in that’s good, eh? After clocking up almost 100 miles locally, playing with the jets, needles, air-screw and stuff, the first run was the Isle of Wight and as a whole the engine did feel keen and eager. The five-speed box was particularly enjoyable (especially after the stronger MB gear spring has worn in a little!).

As for the top end, well it accelerates through the gears very nicely indeed, seems willing enough off the mark, and a GPS reading of 70.1mph shows it has potential, as long as I can be kind to it for the next few miles (I am repeating the “I’m running in” mantra over and over again in my head, but sometimes it is just so tempting to open the throttle wide and race off!).

So what’s next? Well, once the miles have been clocked up I hope to get the scooter on a dyno to get the jetting sorted exactly – and to see what she can offer both in torque and bhp.

Andy